Digital Twin

Enabling simulation verification, physical system control and analysis of trends using computation simulations via AI and machine learning.

The realization of digital engineering requires cultural transformation to enable success. Systems engineering or systems thinking principles must be layered on top of digital engineering tools and capabilities to achieve the required product in the shortest amount of time.

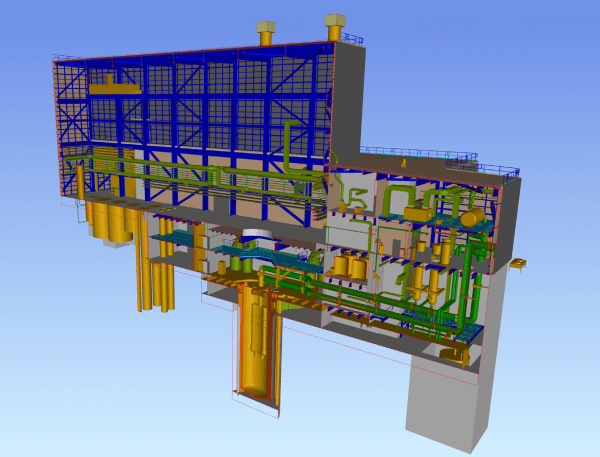

Engineering teams must also migrate from paper-based methodologies to a data-first, data driven future. Systems engineering transitions to model-based systems engineering (MBSE), migrating from document centric paradigms to the exchange of models as a single source of truth for facility design. Drafting migrates from geometry focused computer aided design (CAD) to data focused building information management (BIM) and product lifecycle management (PLM).

A robust cloud environment hosts these software platforms enabling real-time collaboration between disparate project teams across the United States. Workforce strategy, communications, and training are coordinated to execute organizational transformation.

Collaborations & Projects:

The cost of failing to create sufficiently integrated digital engineering systems for large-scale projects is abundantly evident in the nuclear industry and elsewhere. For example, the European Aeronautic Defense & Space (EADS) Airbus 380 program suffered approximately $6.1 billion in losses due to a lack of data integration between design applications used by the various teams. This software interoperability issue caused 20 months of delays and a loss in program confidence (https://www.cadalyst.com/cad/product-design/what-grounded-airbus-a380-10903). On the other hand, when the digital thread is enabled, many positive outcomes will follow. General Electric Digital lists positive outcomes of digital twins including 93–99.49% increased reliability, 40% reduced reactive maintenance, 75% reduced time to achieve outcomes, and the avoidance of $11 million lost in production by detecting and preventing three failures (https://www.ge.com/digital/applications/digital-twin).

|

Defense Nuclear Nonproliferation (DNN) Program

The development of new advanced reactors (Gen IV) increases the importance of new methods to understand diversion and misuse scenarios, and determine mitigation pathways. INL is developing a complete digital twin framework for safeguards by design. This provides the opportunity for comprehensive understanding of nuclear fuel cycle facility operations to significantly strengthen nuclear safeguards and nonproliferation regime.

|

National Reactor Innovation Center (NRIC) Program

The National Reactor Innovation Center (NRIC) has led new advanced demonstration projects using a model-based systems engineering approach. Project requirements are traced to their satisfying elements in SysML and LML-based models used to guide design decisions. Activity models are integrated with Discrete Event and Monte Carlo simulation to check for correctness, integrate cost and schedule, and monitor expected performance. The program is working to develop integrations between MBSE, engineering, operations, and traditional CAD software to enable a cloud-based, digital thread in design.

Capabilities:

Diamond (Data Integration Aggregated Model and Ontology for Nuclear Deployment)

DIAMOND is a nuclear ontology. An ontology is a collection of concepts and relationships within a given domain. It is an extensible document that contains the classes, properties, and relationships that make up that domain. DIAMOND is a Web Ontology Language (OWL) document. OWL is an extension of XML that provides the ability to represent the various constructs in an ontology. DIAMOND acts as a standard taxonomy for the nuclear domain by which data sources can be integrated together through a common format. While DIAMOND is only a data model, when acting as the central schema for Deep Lynx it enables a model to which all integrating data sources can be mapped. https://github.com/idaholab/DIAMOND.

Deep Lynx

A data warehouse technology that can enable the digital thread across an organization by serving as the central point of data aggregation and exchange. Deep Lynx is built on the relational database PostgreSQL, but stores data in a graph-like format. This enables data to be exported to graph databases for analysis and for data to be queried in a graph-like format. When a data source sends data to Deep Lynx, that data is mapped to a central schema (or ontology) in Deep Lynx. This central schema creates a common data format to which all data is mapped. https://github.com/idaholab/Deep-Lynx.

RAVEN

RAVEN (https://raven.inl.gov) is a flexible and multi-purpose probabilistic risk assessment, uncertainty quantification, artificial intelligence, data analysis and model optimization framework. Depending on the tasks to be accomplished and, in case, on the probabilistic (or not) characterization of the problem, RAVEN perturbs (e.g., Monte Carlo, Latin hypercube, reliability surface search, AI-guided, etc.) the response of the system to be analyzed altering the input parameters. The system is modeled by third party software (e.g. RELAP5-3D, MAAP5, BISON, etc.) and accessible to RAVEN either directly (software coupling) or indirectly (via input/output files). The outcomes of the sampling process are analyzed using statistical and data mining approaches. RAVEN also manages the parallel dispatching (i.e. both on desktop/workstation and large HPC systems) of the software representing the physical model. RAVEN relies on artificial intelligence algorithms to construct surrogate models of complex physical systems to accelerate the analysis. RAVEN can be employed for several types of applications, such as UQ, Sensitivity Analysis, PRA, Regression Analysis, Data Mining, Model Optimization, and design of experiments. An overview of the software is resented at raven.inl.gov. The software itself is open-source and can be downloaded at https://github.com/idaholab/raven

Publications:

| Pillar | Date | Citations |

|---|---|---|

| Artificial Intelligence | 2021 | Shaya Wolf, Rita Foster, Jed Haile, Mike Borowczak “Data-Driven Suitability Analysis to Enable Machine Learning Explainability and Security” IEEE Explore |

| Artificial Intelligence | 2021 | Kunz, M. Ross, et al. "Early battery performance prediction for mixed use charging profiles using hierarchal machine learning" Batteries & Supercaps 2021, 4, 1186. |

| Artificial Intelligence | 2021 | Rafer Cooley, Michael Cutshaw, Shaya Wolf, Rita Foster, Jed Haile, Mike Borowczak, 2021, “Comparing Ransomware using TLSH and @DisCo Analysis Frameworks,” Idaho National Lab, National and Homeland Security, Critical Infrastructure Protection, Idaho Falls, ID. |

| Artificial Intelligence | 2021 | Chen, Bor-Rong, et al. "A machine learning framework for early detection of lithium plating combining multiple physics-based electrochemical signatures." Cell Reports Physical Science 2.3 (2021): 100352 |

| Artificial Intelligence | 2021 | Kunz, M. Ross, et al. "Data driven reaction mechanism estimation via transient kinetics and machine learning." Chemical Engineering Journal 420 (2021): 129610. |

| Artificial Intelligence | 2020 | D.P. Guillen, N. Anderson, C. Krome, R. Boza, L. M. Griffel, J. Zouabe, and A. Al Rashdan, 2020, "A RELAP5-3D/LSTM Model for the Analysis of Drywell Cooling Fan Failure," Progress in Nuclear Energy 130, December 2020. https://doi.org/10.1016/j.pnucene.2020.103540. |

| Artificial Intelligence | 2020 | Kunz, M. Ross, et al. "Probability theory for inverse diffusion: Extracting the transport/kinetic time-dependence from transient experiments." Chemical Engineering Journal 402 (2020): 125985 https://www.sciencedirect.com/science/article/pii/S1385894720321136 |

| Artificial Intelligence | 2020 | Manjunatha, K, A. L. Mack, V. Agarwal, D. Adams, and D. Koester, 2020, "Diagnosis of corrosion processes in nuclear power plants secondary piping structures", ASME Pressure Vessels and Piping Conference, July – August (held virtually). |

| Artificial Intelligence | 2020 | Gentillon, C., C. L. Atwood, A. L. Mack, and Z. Ma, 2020, "Evaluation of weakly informed priors for FLEX data", INL/EXT-20-58327, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2020 | Garcia, H., S. Aumeier, A. Al Rashdan, and B. Rolston, 2020, "Secure embedded intelligence in nuclear systems: Framework and method", Annals of Nuclear Energy, accepted for publication. DOI:10.1016/j.anucene.2019.107261. |

| Artificial Intelligence | 2019 | V. Narcisi, P. Lorusso, F. Giannetti, A. Alfonsi, G. Caruso, "Uncertainty Quantification method for RELAP5-3D© using RAVEN and application on NACIE experiments", Annals of Nuclear Energy, vol. 127, pp. 419-432, 2019 |

| Artificial Intelligence | 2019 | A. S. Epiney, A. Alfonsi, C. Parisi, R. Szilard, "RISMC Industry Application #1 (ECCS/LOCA): Core characterization automation: Lattice Codes interface for PHISICS/RELAP5-3D", Nuclear Engineering and Design, 345, pp-15-27, 2019 |

| Artificial Intelligence | 2019 | A. Alfonsi, C. Wang, J. Cogliati, D. Mandelli, C. Rabiti "Status of Adaptive Surrogates within the RAVEN framework", Idaho National Laboratory, Idaho Falls, Idaho, INL/EXT 17 43438 |

| Artificial Intelligence | 2019 | Guillen, D., N. Anderson, C. Krome, R. Boza, M. Griffel, J. Zouabe, and A. Al-Rashdan, 2019, "The application of physics-informed machine-learning to predict drywell cooling fan failure", Proceedings of the Big Data for Nuclear Power Plants Workshop 2019. |

| Artificial Intelligence | 2019 | Garcia, H., S. Aumeier, and A. Al Rashdan, 2019, "Integrated state awareness through secure embedded intelligence in nuclear systems: Opportunities and implications", Nuclear Science and Engineering, accepted for publication. DOI:10.1080/00295639.2019.1698237. |

| Artificial Intelligence | 2019 | Al Rashdan, A., M. Griffel, R. Boza, and D. P. Guillen, 2019, "Subtle process anomalies detection using machine learning methods", INL/EXT-19-55629, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2019 | Al Rashdan, A., C. Krome, S. St. Germain, J. Corporan, K. Ruppert, and J. Rosenlof, 2019, "Method and application of data integration at a nuclear power plant", INL/EXT-19-54294, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2019 | Al Rashdan, A. and D. Roberson, 2019, "A frequency domain control perspective on xenon resistance for load following of thermal nuclear reactors", IEEE Transactions on Nuclear Science., Vol. 66, No. 9, pp. 2034–2041. |

| Artificial Intelligence | 2018 | A. Alfonsi, A. Hummel, J. Chen, G. Strydom, H. Gougar, "Decay Heat Surrogate modeling for High Temperature Reactors", Proceedings of HTR 2018, Warsaw, Poland, October 8-10, 2018 |

| Artificial Intelligence | 2018 | C. Rabiti, A. Alfonsi, A. S. Epiney, "New Simulation Schemes and Capabilities for the PHISICS/RELAP5-3D Coupled Suite", Nuclear Science and Engineering, vol.182, num. 1, pp 104-118 |

| Artificial Intelligence | 2018 | A. Alfonsi, G. Mesina, A. Zoino, N. Anderson, C. Rabiti, "Combining RAVEN, RELAP5-3D and PHISICS for Fuel Cycle and Core Design Analysis", ASME Journal of Nuclear Engineering and Radiation Science, vol. 3, num. 2, # NERS-16-1120 |

| Artificial Intelligence | 2018 | D. Mandelli, D. Maljovec, A. Alfonsi, C. Parisi, P. Talbot, J. Cogliati, C. Smith, "Mining data in a dynamic PRA framework", Progress in Nuclear Energy, 108, 99-110, September 2018. |

| Artificial Intelligence | 2018 | Kunz, M. Ross, et al. "Pulse response analysis using the Y-procedure: A data science approach." Chemical Engineering Science 192 (2018): 46-60 https://www.sciencedirect.com/science/article/pii/S0009250918304561 |

| Artificial Intelligence | 2018 | Medford, Andrew J., et al. "Extracting knowledge from data through catalysis informatics." ACS Catalysis 8.8 (2018): 7403-7429 https://pubs.acs.org/doi/10.1021/acscatal.8b01708 |

| Artificial Intelligence | 2018 | Mandelli, D., C. Wang, S. Staples, C. S. Ritter, A. L. Mack, S. W. St. Germain, A. Alfonsi, C. Rabiti, and R. Kunz, 2018, "Cost risk analysis framework (CRAFT): An integrated risk analysis tool and its application in an industry use case", INL/EXT-18-51442, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2018 | Al Rashdan, A., and T. Mortenson, 2018, "Automation technologies impact on the work process of nuclear power plants", INL/EXT-18-51457, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2018 | Al Rashdan, A., J. Smith, S. St. Germain, C. Ritter, V. Agarwal, R. Boring, T. Ulrich, and J. Hansen, 2018, "Development of a technology roadmap for online monitoring of nuclear power plants", INL/EXT-18-52206, Idaho Falls, ID, USA. |

| Artificial Intelligence | 2017 | C. Picoco, T. Aldemir, V. Rychkov, A. Alfonsi, D. Mandelli, C. Rabiti, "Coupling of RAVEN and MAAP5 for the Dynamic Event Tree analysis of Nuclear Power Plants", proceedings of European Safety and Reliability Conference - ESREL, June 18-22, 2017, Portoroz, Slovenia |

| Artificial Intelligence | 2017 | A. Alfonsi, C. Rabiti, D. Mandelli, "Assembling Multiple Models within the RAVEN Framework", Proceedings of 2017 American Nuclear Society Annual Meeting, June 11-15, 2017, San Francisco |

| Artificial Intelligence | 2017 | A. Alfonsi, C. Wang, D. Mandelli, C. Rabiti, "Adaptive Surrogates within the RAVEN Framework for Dynamic Probabilistic Risk Assessment Analysis", Proceeding of Best Estimate Plus Uncertainty International Conference, Lucca, Italy, May 13-18. |

| Artificial Intelligence | 2016 | A. Alfonsi, D. Mandelli, C. Rabiti "RAVEN Facing the Problem of assembling Multiple Models to Speed up the Uncertainty Quantification and Probabilistic Risk Assessment Analyses" Proceedings of 13th International Conference on Probabilistic Safety Assessment and Management (PSAM 13), Oct. 2-6 2016, Seul, South Korea |

| Artificial Intelligence | 2016 | A. Alfonsi, G. Mesina, A. Zoino, C. Rabiti "A fuel cycle and core design analysis method for new cladding acceptance criteria using PHISICS, RAVEN and RELAP5-3D" Proceedings of the 24th International Conference on Nuclear Engineering (ICONE24), June 26-30, 2016, Charlotte, USA |

| Artificial Intelligence | 2015 | A. Alfonsi, C. Rabiti, D. Mandelli, J. Cogliati, S. Sen, C. Smith, "Improving Limit Surface Search Algorithms in RAVEN Using Acceleration Schemes," INL/EXT-15-36100, July 2015 |

| Artificial Intelligence | 2015 | D. Mandelli, A. Alfonsi, C. Smith, C. Rabiti, "Generation and Use of Reduced Order Models for Safety Applications Using RAVEN", Proceedings American Nuclear Society 2015 Winter Meeting, November 8-12, 2015, Washington, DC, US |

| Artificial Intelligence | 2015 | Farber, J., D. Cole, A. Al Rashdan, and V. Yadav, 2019. "Using kernel density estimation to detect loss-of-coolant accidents in a pressurized water reactor", Nuclear Technology, special issue on Big Data for Nuclear Power Plants, 205(8):1043–1052. |

| Artificial Intelligence | 2015 | Agarwal, V., N. Lybeck, B. Pham, R. Rusaw, and R. Bickford, 2015, "Prognostic and health management of active assets in nuclear power plants", International Journal of Prognostics and Health Management, Special Issue on Nuclear Energy PHM, 6:1–17. |

| Artificial Intelligence | 2015 | Agarwal, V., N. Lybeck, B. Pham, R. Rusaw, and R. Bickford, 2015, "Asset fault signatures for prognostic and health management in the nuclear industry", IEEE Reliability Digest, February 2015. |

| Artificial Intelligence | 2014 | C. Rabiti, D. Mandelli, A. Alfonsi, J. Cogliati, R. Kinoshita :Introduction of Supervised Learning Capabilities of the RAVEN Code for Limit Surface Analysis", Proceedings American Nuclear Society 2014 Annual Meeting, June 15-19, 2014, Reno, NV, US |

| Artificial Intelligence | 2014 | Alamamiotis, M., and V. Agarwal, 2014, "Fuzzy integration of support vector regression models for anticipatory control of complex energy systems", International Journal of Monitoring and Surveillance Technologies Research, 2(2):26–40. |

| Artificial Intelligence | 2013 | D. Mandelli, C. Smith, C. Rabiti, A. Alfonsi, R. Youngblood, V. Pascucci, B. Wang, D. Maljovec, P. T. Bremer “Dynamic PRA: An Overview of New Algorithms to Generate, Analyze and Visualize Data, Proceedings American Nuclear Society 2013 Winter Meeting, November 10-14, 2013, Washington, DC |

| Artificial Intelligence | 2008 | Yonge, Adam, et al. "TAPsolver: A Python package for the simulation and analysis of TAP reactor experiments." arXiv preprint arXiv:2008.13584 (2020) https://arxiv.org/abs/2008.13584 |

| Computing Platforms | 2021 | Biaggne, A., Knowlton, W., Yurke, B., Lee, J., & Li, L. (2021). Substituent Effects on the Solubility and Electronic Properties of the Cyanine Dye Cy5: Density Functional and Time-Dependent Density Functional Theory Calculations. Molecules 26 524-524. https://doi.org/10.3390/molecules26030524 |

| Computing Platforms | 2021 | Li, Z., Zhan, X., Bai, X., Lee, S., Zhong, W., Sutton, B., Heuser, B., (2021). Modified Microstructures in Proton Irradiated Dual Phase 308L Weldment Filler Material. Journal of Nuclear Materials 548 152825-152825. https://doi.org/10.1016/j.jnucmat.2021.152825 |

| Computing Platforms | 2021 | Manzoor, A., Zhang, Y., & Aidhy, D. (2021). Factors affecting the vacancy formation energy in Fe70Ni10Cr20 random concentrated alloy. Computational Materials Science 110669-110679. |

| Computing Platforms | 2021 | Greenquist, I., Cunningham, K., Hu, J., Powers, J., & Crawford, D. (2021). Development of a U-19Pu-10Zr fuel performance benchmark case based on the IFR-1 experiment. Journal of Nuclear Materials 553 152997-152997. |

| Computing Platforms | 2021 | Bajpai, P., Poschmann, M., & Piro, M. (2021). Derivations of Partial Molar Excess Gibbs Energy of Mixing Expressions for Common Thermodynamic Models. Journal of Phase Equilibria and Diffusion 1-15. https://doi.org/10.1007/s11669-021-00886-w |

| Computing Platforms | 2021 | Merzari, E., Gaston, D., Martineau, R., Fischer, P., Hassan, Y., Haomin, Y., Min, M., Shaver, D., Rahaman, R., Shriwise, P., Romano, P., Talamo, A., Lan, Y., (2021). Cardinal: A Lower-Length-Scale Multiphysics Simulator for Pebble Bed Reactors. Nuclear Technology 7 1118-1141. https://doi.org/10.1080/00295450.2020.1824471 |

| Computing Platforms | 2021 | Zhang, Y., Manzoor, A., Jiang, C., Aidhy, A., & Schwen, D. (2021). A statistical approach for atomistic calculations of vacancy formation energy and chemical potentials in concentrated solid-solution alloys. Computational Materials Science 190 110308-110312. |

| Computing Platforms | 2021 | Biaggne, A., Noble, G., & Li, L. (2021). Adsorption and Surface Diffusion of Metals on a-Al2O3 for Advanced Manufacturing Applications. JOM 73 1062-1070. https://doi.org/10.007/s11837-021-04589-y |

| Computing Platforms | 2021 | Greenquist, I., & Powers, J. (2021). 25-Pin metallic fuel performance benchmark case based on the EBR-II X430 experiment series. Journal of Nuclear Materials 556 153211-153211. |

| Computing Platforms | 2021 | Merzari, E., Gaston, D., Martineau, R., Fischer, P., Hassan, Y., Haomin, Y., Min, M., Shaver, D., Rahaman, R., Shriwise, P., Romano, P., Talamo, A., Lan, Y., (2021). Cardinal: A Lower-Length-Scale Multiphysics Simulator for Pebble Bed Reactors. Nuclear Technology 7 1118-1141. https://doi.org/10.1080/00295450.2020.1824471 |

| Computing Platforms | 2021 | Zongtang Fang, Matthew P. Confer, Yixiao Wang, Qiang Wang, M. Ross Kunz, Eric J. Dufek, Boryann Liaw, Tonya M. Klein, David A. Dixon*, and Rebecca Fushimi*, "Formation of Surface Impurities on Lithium Nickel Manganese Cobalt Oxides in the Presence of CO2 and H2O", July 2, 2021 https://doi.org/10.1021/jacs.1c03812 |

| Computing Platforms | 2019 | Jin, M., Cao, P., & Short, M. (2020). Achieving exceptional radiation tolerance with crystalline-amorphous nanocrystalline structures. Acta Materialia 186 587-596. https://doi.org/10.1016/j.actamat.2019.12.058 |

| Computing Platforms | 2018 | https://inldigitallibrary.inl.gov/sites/sti/sti/Sort_14693.pdf |

| Resilient Controls and Instrumentation Systems | 2021 | TB Phillips, TR McJunkin, CG Rieger, JF Gallego-Calderon, JP Lehmer, Idaho National Lab (INL), Idaho Falls, ID (United States), 2021/8/6 "Power Distribution Designing For Resilience Application" |

| Resilient Controls and Instrumentation Systems | 2021 | G Michail Makrakis, C Kolias, G Kambourakis, C Rieger, J Benjamin, arXiv e-prints, arXiv: 2109.03945, 2021/9, "Vulnerabilities and Attacks Against Industrial Control Systems and Critical Infrastructures" |

| Resilient Controls and Instrumentation Systems | 2021 | CS Wickramasinghe, K Amarasinghe, DL Marino, C Rieger, M Manic IEEE Access, 2021/9/14, "Explainable Unsupervised Machine Learning for Cyber-Physical Systems" |

| Resilient Controls and Instrumentation Systems | 2017 | "Data Fidelity: Security's Soft Underbelly" (RCIS 2017),"Data Fidelity in the Post-Truth Era" (ICCWS 2018) |

| Decision Science, Visualization and Human Computer Interaction | 2021 | Nguyen RT, Lionel Toba DA, Severson MH, Woodbury E, Carey A, Imholte DD. A market-oriented database design for critical material research. The Journal of The Minerals, Metals & Materials Society (JOM). 2021 Jun 30;1(INL/JOU-21-61669-Rev000). |

| Decision Science, Visualization and Human Computer Interaction | 2021 | Toba AL, Nguyen RT, Cole C, Neupane G, Paranthaman MP. US lithium resources from geothermal and extraction feasibility. Resources, Conservation and Recycling. 2021 Jun 1;169:105514. |

| Decision Science, Visualization and Human Computer Interaction | 2021 | Burli PH, Nguyen RT, Hartley DS, Griffel LM, Vazhnik V, Lin Y. Farmer characteristics and decision-making: A model for bioenergy crop adoption. Energy. 2021 Jun 15:121235. |

| Decision Science, Visualization and Human Computer Interaction | 2021 | Hossain T, Jones D, Hartley D, Griffel LM, Lin Y, Burli P, Thompson DN, Langholtz M, Davis M, Brandt C. The nth-plant scenario for blended feedstock conversion and preprocessing nationwide: Biorefineries and depots. Applied Energy. 2021 Jul 15;294:116946. |

| Decision Sciences & Visualization | 2020 | Abou Ali, H., Delparte, D., & Griffel, L. M. (2020). From Pixel to Yield: Forecasting Potato Productivity in Lebanon and Idaho. The International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences, 42, 1-7. DOI: 10.5194/isprs-archives-XLII-3-W11-1-2020. |

| Decision Sciences & Visualization | 2020 | Griffel, L. M., Vazhnik, V., Hartley, D. S., Hansen, J. K., and Roni, M. 2020. Agricultural field shape descriptors as predictors of field efficiency for perennial grass harvesting: An empirical proof. Computers and Electronics in Agriculture (168)105088. DOI: 10.1016/j.compag.2019.105088 |

| Decision Sciences & Visualization | 2020 | Meyer, P. A., Snowden-Swan, L. J., Jones, S. B., Rappe, K. G. and Hartley, D. S. 2020. The effect of feedstock composition on fast pyrolysis and upgrading to transportation fuels: Techno-economic analysis and greenhouse gas life cycle analysis. Fuel (259)116218. DOI:10.1016/j.fuel.2019.116218 |

| Decision Sciences & Visualization | 2020 | Wahlen, B. D., Wendt, L. M., Murphy, A., Thompson, V. S., Hartley, D. S., Dempster, T. and Gerken, H. 2020. Preservation of Microalgae, Lignocellulosic Biomass Blends by Ensiling to Enable Consistent Year-Round Feedstock Supply for Thermochemical Conversion to Biofuels. Frontiers in Bioengineering and Biotechnology.(8)316. DOI:10.3389/fbioe.2020.00316 |

| Decision Sciences & Visualization | 2020 | Wang, Y, Wang, J, Schuler, J, Hartley, D., Volk, T and Eisenbies, M. 2020. Optimization of harvest and logistics for multiple lignocellulosic biomass feedstocks in the northeastern United States. Energy (197)117260. DOI: 10.1016/j.energy.2020.117260. |

| Decision Sciences & Visualization | 2020 | Hartley, D.S., Thompson, D. N.; Griffel, L. M., Nguyen, Q. A and Roni, M.S. 2020. The effect of biomass properties and system configuration on the operating effectiveness of biomass to biofuel systems. ACS Sustainable Chemistry & Engineering. In Press. DOI: 10.1021/acssuschemeng.9b06551 |

| Decision Science, Visualization and Human Computer Interaction | 2020 | Toba, A.L., Griffel, L.M., & Hartley, D.S., (2020). Devs Based Modeling and Simulation of Agricultural Machinery Movement. In Press, Computers and Electronics in Agriculture. |

| Decision Science, Visualization and Human Computer Interaction | 2019 | Narani, A., Konda, N.V.S.N.M, Chen, C.-S., Tachea, F., Coffman, P., Gardner, J., Li, C., Ray, A.E., Hartley, D.S., Simmons, B., Pray, T.R., Tanjore, D. 2019. Simultaneous application of predictive model and least cost formulation can substantially benefit biorefineries outside Corn Belt in United States: A case study in Florida. Bioresource Technology. 271:218-227. |

| Decision Science, Visualization and Human Computer Interaction | 2019 | Langholtz, M., Davis, M., Hartley, D., Brandt, C., Hilliard, M., Eaton, L. 2019. Cost and profit impacts of modifying stover harvest operations to improve feedstock quality. Biofuels, Bioproducts & Biorefining. |

| Decision Science, Visualization and Human Computer Interaction | 2019 | Roni, M.S., Thompson, D.N. and Hartley, D.S., 2019. Distributed biomass supply chain cost optimization to evaluate multiple feedstocks for a biorefinery. Applied Energy, 254, p.113660. |

| Decision Science, Visualization and Human Computer Interaction | 2019 | Jin, H., Reed, D. W., Thompson, V. S., Fujita, Y., Jiao, Y., Crain-Zamora, M., Fisher, J., Scalzone, K., Griffel, L. M., Hartley, D. and Sutherland, J. W. (2019). Sustainable bioleaching of rare earth elements from industrial waste materials using agricultural wastes. ACS Sustainable Chemistry & Engineering, 7(18), pp.15311-15319. DOI: 10.1021/acssuschemeng.9b02584. |

| Decision Science, Visualization and Human Computer Interaction | 2019 | Hansen, J. K., Roni, M. S., Nair, S. K., Hartley, D. S., Griffel, L. M., Vazhnik, V., & Mamun, S. 2019. Setting a baseline for Integrated Landscape Design: Cost and risk assessment in herbaceous feedstock supply chains. Biomass and Bioenergy, 130. doi:10.1016/j.biombioe.2019.105388 |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Nair, S. K., Griffel, L. M., Hartley, D. S., McNunn, G. S., & Kunz, M. R. (2018). Investigating the efficacy of integrating energy crops into non-profitable subfields in Iowa. BioEnergy Research, 11, pp. 623-637. DOI: 10.1007/s12155-018-9925-0. |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Olsson, O., Roos, A., Guisson, R., Bruce, L., Lamers, P., Hektor, B., Thrän, D., Hartley, D., Ponitka, J. and Hildebrandt, J., 2018. Time to tear down the pyramids? A critique of cascading hierarchies as a policy tool. Wiley Interdisciplinary Reviews: Energy and Environment.7(2),e279 |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Griffel, L. M., Delparte, D., & Edwards, J. (2018). Using Support Vector Machines classification to differentiate spectral signatures of potato plants infected with Potato Virus Y. Computers and Electronics in Agriculture, 153, 318-324. DOI: 10.1016/j.compag.2018.08.027. |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Roni, M.S., Thompson, D., Hartley, D., Searcy, E. and Nguyen, Q., 2018. Optimal blending management of Biomass Resources Used for Biochemical Conversion. Biofuels, Bioproducts and Biorefining. 12(4):624-648 |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Lamers, P., Nyugen,R., Hartley, D., Hansen, J. and Searcy, E., 2018. Biomass market dynamics supporting the large-scale deployment of high-octane fuel production in the United States. GCB Bioenergy. 10(7):460-472 |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Wendt, L.M., Smith, W.A., Hartley, D.S., Wendt, D.S., Ross, J.A., Sexton, D.M., Lukas, J.C, Nguyen, Q.A., Murphy, A.J., Kenney, K.L. 2018. Techno-economic assessment of a chopped feedstock logistics supply chain for corn stover. Frontiers in Energy Research. 6(90). |

| Decision Science, Visualization and Human Computer Interaction | 2018 | Emerson, R.M., Hernandez, S., Williams, C.L., Lacey, J.A., Hartley, D.S. 2018. Improving bioenergy feedstock quality of high moisture short rotation woody crops using air classification. Biomass and Bioenergy. 117:56-62 |

| Decision Science, Visualization and Human Computer Interaction | 2017 | Wendt, L.M., Wahlen, B.D., Li, C., Ross, J.A., Sexton, D.A., Lukas, J.A., Hartley, D.S. and Murphy, J.A., 2017. Evaluation of a high-moisture stabilization strategy for harvested microalgae blended with herbaceous biomass: Part II- techno-economic assessment. Algal Research. 25:676-685 |

| Decision Science, Visualization and Human Computer Interaction | 2017 | Liu, W, Wang, J., Richard, T., Hartley, D., Spatari, S., Volk,T., 2017. Economic and Life Cycle Analyses of Biomass Utilization for Bioenergy and Bioproducts. Biofuels, Bioproducts & Biorefining. 11(4):633-647 |

| Decision Science, Visualization and Human Computer Interaction | 2017 | Narani, A., Coffman, P., Gardner, J., Li, C., Ray, A.E., Hartley, D.S., Stettler, A., Konda, S.N.M., Simmons, B., Pray, T., Tanjore, D., 2017. Predictive modeling to de-risk bio-based manufacturing by adapting to variability in lignocellulosic biomass supply, Bioresource Technology.243:676-685 |

| Decision Science, Visualization and Human Computer Interaction | 2016 | Thompson, V.S., Lacey, J.A., Hartley, D.S., Jindra, M. A., Aston, J. E., Thompson, D. N., 2016. Application of air classification and formulation to manage feedstock cost, quality and availability for bioenergy. Fuel, 180: 497-505. |

| Digital Thread | 2021 | Christopher Ritter, Ashley Shields, Ross Hays, Jeren Browning, Ryan Stewart, Samuel Bays, Gustavo Reyes, Mark Schanfein, Adam Pluth, Piyush Sabharwall, Ross Kunz, John Koudelka, Porter Zohner, "NNSA Digital Twin: Explainable AI Report", August 20, 2021. |

| Digital Thread | 2021 | Jeren Browning, Andrew Slaughter, Ross Kunz, Joshua Hansel, Bri Rolston, Katherine Wilsdon, Adam Pluth, Dillon McCardell. "Foundations for a Fission Battery Digital Twin", August 16, 2021. |

| Digital Thread | 2021 | Christopher Ritter, Ross Hays, Jeren Browning, Ryan Stewart, Samuel Bays, Gustavo Reyes, Mark Schanfein, Adam Pluth, Piyush Sabharwall, Ross Kunz, Ashley Shields, John Koudelka, Porter Zohner, "Digital Twin to Detect Nuclear Proliferation: A Case Study" August 10, 2021. |

| Digital Thread | 2021 | Ross Hays, Peter Suyderhoud, Jeren Browning, Christopher Ritter. "Requirements Management and Data Models for the Versatile Test Reactor", June 21, 2021. |

| Digital Thread | 2021 | Christopher Ritter, Lee Nelson, Jeren Browning, AnnMarie Marshall, Ross Hays, Taylor Ashbocker, Peter Suyhderhoud, John Darrington, "Versatile Test Reactor Open Digital Engineering Ecosystem", June 7, 2021. |

| Digital Thread | 2021 | Ross Hays, Christopher Ritter, Jeren Browning, Samuel Bays, Gustavo Reyes, Mark Schanfein, Adam Pluth, Piyush Sabharwall, Ross Kunz, Ashley Shields, John Koudelka, "Data Model for Analysis of Proliferation Resistance", January 14, 2021. |

| Digital Thread | 2020 | Ahmad Al Rashdan, Cameron Krome, Jeren Browning, Kellen Giraud, Jared Wadsworth, Shawn St Germain, "Use Cases of DIAMOND for Data-Enabled Automation in Nuclear Power Plants", September 23, 2020. |

| Digital Thread | 2020 | Christopher Ritter, Jeren Browning, "Towards a Digital Twin to Detect Nuclear Proliferation Activities", September 8, 2020. |

| Digital Thread | 2019 | Christopher Ritter, Jeren Browning, Lee Nelson, Tammie Borders, John Bumgardner, Mitchell Kerman, "Digital Engineering Ecosystem for Future Nuclear Power Plants: Innovation of Ontologies, Tools, and Data Exchange", October 29, 2019. |

| Digital Thread | 2019 | Ahmad Al Rashdan, Jeren Browning, Christopher Ritter, "Data Integration Aggregated Model and Ontology for Nuclear Deployment (DIAMOND): Preliminary Model and Ontology", September 11, 2019. |

| Digital Twin | 2020 | NL/JOU-21-63018, Versatile Test Reactor Open Digital Engineering Ecosystem |

| Digital Twin | 2020 | INL/JOU-21-63077, Requirements Management and Data Models for the Versatile Test Reactor |

| Digital Twin | 2019 | Christopher Ritter, Jeren Browning, Lee Nelson, Tammie Borders, John Bumgardner, Mitchell Kerman, "Digital Engineering Ecosystem for Future Nuclear Power Plants: Innovation of Ontologies, Tools, and Data Exchange", October 29, 2019. |

| Instrumentation and Controls | 2019 | M. A. S. Zaghloul, A. M. Hassan, D. Carpenter, P. Calderoni, J. Daw and K. P. Chen, "Optical Sensor Behavior Prediction using LSTM Neural Network," 2019 IEEE Photonics Conference (IPC), 2019, pp. 1-2, doi: 10.1109/IPCon.2019.8908337. |

| Instrumentation and Controls | 2019 | P. Calderoni, D. Hurley, J. Daw, A. Fleming and K. McCary, "Innovative sensing technologies for nuclear instrumentation," 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), 2019, pp. 1-6, doi: 10.1109/I2MTC.2019.8827129. |

| Instrumentation and Controls | 2014 | Troy Unruh, Benjamin Chase, Joy Rempe, David Nigg, George Imel, Jason Harris, Todd Sherman & Jean-Francois Villard (2014) In-Core Flux Sensor Evaluations at the ATR Critical Facility, Nuclear Technology, 187:3, 308-315, DOI: 10.13182/NT13-122 |

| Instrumentation and Controls | 2011 | Bong Goo Kim, Joy L. Rempe, Jean-François Villard & Steinar Solstad (2011) Review Paper: Review of Instrumentation for Irradiation Testing of Nuclear Fuels and Materials, Nuclear Technology, 176:2, 155-187, DOI: 10.13182/NT11-A13294 |

| Practice and Culture | 2019 | Christopher Ritter, Jeren Browning, Lee Nelson, Tammie Borders, John Bumgardner, Mitchell Kerman, "Digital Engineering Ecosystem for Future Nuclear Power Plants: Innovation of Ontologies, Tools, and Data Exchange", October 29, 2019. |

| Decision Science, Visualization and Human Computer Interaction | 2022 | Khadka, R., Koudelka, J., Kenney, K., Egan, E. Casanova, K., Hillman, B., Reed, T., Newman, G., & Issac, B. (2022, March). Mobile Hot Cell Digital Twin: End-of-life Management of Disused High Activity Radioactive Sources – 22057. In Waste Management Symposia (WMS) |